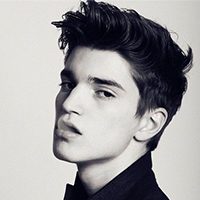

Columbus, Ohio — Viruses can be scary, and COVID-19 reminded us why. “We can prevent viral diseases quite well by vaccination,” says Adam Kovalčík, 19. But once someone is infected, he says, “it’s very hard to cure them.” This high school senior at Gymnázium Nové Zámky in Slovakia hopes to change that with some clever chemistry.

Adam invented a process for turning an alcohol made from corn husks and cobs into galidesivir. This drug is not yet approved by the U.S. Food & Drug Administration for use, but it is undergoing human trials. Its developer hopes it might one day quash Ebola, Zika and many other killer diseases caused by RNA viruses. And the technique Adam used to make that drug might pave the way for more life-saving medicines, as well.

COVID-19 turned a spotlight onto antiviral drugs, including galidesivir. Side effects often cause many antiviral drugs to do more harm than good, says Adam. But galidesivir is different. Early data suggest it has few side effects. So if approved for use on patients, it could help a lot of people.

In fact, it “could potentially save tens of thousands of lives,” Adam says — except for one not-so-tiny problem. Early work showed it was really expensive to make: at least $75 per gram (0.035 ounce).

Adam now reports his new process should dramatically lower that cost to just $12.50 a gram.

For his achievement, Adam today won the $100,000 George D. Yancopoulos Innovator Award. It’s the top prize, here, at the 2025 Regeneron International Science and Engineering Fair, or ISEF.

What’s been the problem?

Often when a chemist mixes up drugs in the lab, the first batch can contain a lot of unwanted material. That bonus stuff can include variants of the drug. These are known as stereoisomers. They contain the same chemical formula, but their atoms are arranged in a slightly different way. (For example, the structure of one molecule might be a mirror-image of another, like the difference between your left and right hands.)

Adam wanted to make what’s known as cis-OH galidesivir. It works about 20 times better than its stereoisomer, trans-OH galidesivir, he says. To get a potent version of the drug, chemists pull the trans version out so that only (or mostly) the cis remains. Those separation steps boost the cost and time in making a drug.

Adam had worked in chemistry labs before. So he had some idea of how to begin redesigning a drug-making process.

You begin with a starter molecule. For galidesivir, that starter had been a sugar. If Adam started with a sugar, he’d wind up with the old, inefficient process. So he looked to start with something else.

Inspired by perfume-making

Earlier, Adam had worked on perfumes in a chemistry lab. He knew corn wastes could be used to make furfuryl alcohol, a starter molecule for some scent compounds.

“I knew a lot of the reactions that you can do with these starting materials,” he says. That gave him reason to believe he could adapt furfuryl alcohol into galidesivir.

Starting with this alcohol, Adam needed only 10 chemical steps to make galidesivir. That was a very streamlined process. In the past, it has taken chemists about 15 steps to turn a starting sugar into this drug.

Adam compares what he did to building with Lego blocks. “We basically slowly built the [drug] molecule block by block,” he says. “Just like Legos, we build it up in the way we want.”

Using a new starting material allowed Adam to develop a process that makes mostly the cis version of galidesivir. And he doesn’t think this tech’s value is only in making galidesivir. It should work to make other antivirals, too, he says.

These drugs work by binding to molecules in our cells that are key to helping viruses copy themselves. The drugs keep a virus from using those molecules. Galidesivir, for instance, blocks an enzyme known as RNA polymerase (Puh-LIM-er-ace).

Adam used a computer to model new molecules that should work the same way as galidesivir at shutting down viral reproduction. One of them, which he calls ADK-98, could work even better. And using corn alcohol as a building block for such drugs, he says, should keep their costs low, too.

Regeneron ISEF is a program created and run by the Society of Science (which also publishes this magazine). Adam was among 1657 students — from 62 nations or territories — who competed at the 75th annual ISEF. These participants shared nearly $9 million in prizes.

Do you have a science question? We can help!

Submit your question here, and we might answer it an upcoming issue of Science News Explores